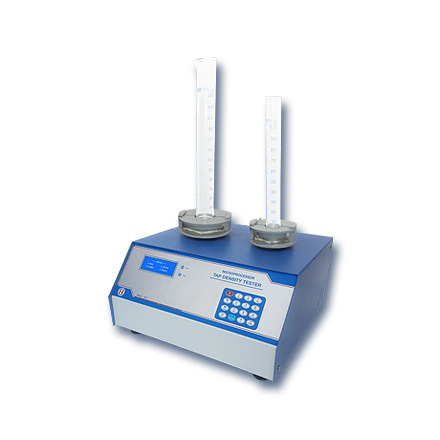

Tap Density Tester - 1951

Tap Density Tester - 1951 Specification

- Dimension (L*W*H)

- 240 x 300 x 350 Millimeter (mm)

- Weight

- 10-20 Kilograms (kg)

- Power

- 10 Watt (w)

- Voltage

- 220 Volt (v)

- Material

- Plastic

Tap Density Tester - 1951 Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 15 Pieces Piece Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Western Europe, Asia, Australia, Middle East, Central America, Africa, South America, Eastern Europe, North America

- Main Domestic Market

- All India

About Tap Density Tester - 1951

FEATURES

- Complies with USP, IP specifications

- Extremely useful for pharmaceutical labs

- Microprocessor based, easy to use

- 20 x 4 line alphanumeric LCD display with backlit

- 16 Soft touch membrane type keys

- Independent programmable setups for User & USP mode with storage

- Rs232 Printer attachment facility

- Automatically calculate result parameters like Tap Density, Initial Density, Compressibility Index and Hausner Ratio

- Automatically stores last Result

- Power Failure detection facility

- User friendly operation with menus & current status indicators.

Microprocessor Tap Density Tester, Model 1951 is a density measurement equipment used to measure tapped density of powders, as well as granulated or flaked materials by standardized and repeatable procedures. Instrument uses the latest microprocessor technology and advanced engineering techniques so as to give enhanced accuracy and reproducibility.

System is equipped with 4 line alphanumeric LCD display with backlit and 16 number of soft touch membrane type keys.

The unit is provided with two motorized platforms which allow for 14 + 2.0 mm drop height for the USP Method I version, and a 3 +0.3 mm drop height for the USP Method II version. The motorized platforms consist of two cylinder holders with snap-lock mechanism designed to hold 100 ml and 250 ml cylinders. The simultaneous rotating and tapping motion minimizes any possible loss of mass during tapping down.

The instrument stores the test parameters, readings and results simultaneously in the memory which are retained even after the power is switched OFF. Provision has also been made for attachment of a printer so as to provide hard-copy printouts of test data, including the time, date and calculated results.

SPECIFICATIONS

| Test Methods |

USP-I & USP-II |

| No. of Stations |

2 |

| Display | 20x4 Alphanumeric LCD |

| Keyboard | 16 Soft touch membrane keys, alphanumeric mobile keypad |

| Tap Height | USP-I: 14mm +2mm, USP-II: 3mm + 0.3mm |

| Taps/Minute | USP-I: 300 + 15, USP-II: 250 + 15 |

| No. of Tap Counts |

1 to 9999 |

| Type of Drive |

Direct Drive with Stepper Motor |

| Printer Accessories | Attachment of RS232 printer with Serial interface |

| Standard Accessories | Cylinders 100 & 250ml (1 each) Cylinder holders for 100 & 250ml (1 each) |

| Electrical Supply |

230 V AC + 10%, 50/60 Hz, 44VA |

| Dimensions (WxHxD) |

360x340x190 mm without holder |

| Weight | 15 Kgs |

Note : Specifications are subject to change due to continuous improvements.

Efficient Tap Density Measurement

The Tap Density Tester - 1951 delivers consistent measurements, supporting precise determination of powder bulk density. Its robust plastic body ensures long-term use, while the optimal dimensions make it suitable for most laboratory workbenches. These features allow researchers and industrial users to achieve accurate results, essential for quality assurance and process optimization.

Designed for Laboratory Use

With a weight range of 10-20 kg and a power requirement of only 10 Watts, the Tap Density Tester is exceptionally energy-efficient and easy to handle. Operating at a standard 220 Volt supply, it can be seamlessly installed in laboratories and manufacturing environments across India and abroad, without the need for complex setup.

FAQs of Tap Density Tester - 1951:

Q: How do you operate the Tap Density Tester - 1951?

A: To operate the Tap Density Tester - 1951, place the powder sample into the designated chamber, set the required number of taps, and switch on the device. The tester will automatically perform tapping cycles to compact the powder, after which you can measure the resulting density.Q: What materials is the Tap Density Tester - 1951 made from?

A: This tester is constructed primarily from durable plastic, which ensures longevity and resistance to chemical corrosion, making it ideal for laboratory and industrial use.Q: When should I use the Tap Density Tester - 1951 in my laboratory process?

A: Use the Tap Density Tester during quality control or material research phases whenever precise measurement of powder compaction or bulk density is required, especially for optimizing formulations or ensuring product consistency.Q: Where is the Tap Density Tester - 1951 manufactured and available for export?

A: The Tap Density Tester - 1951 is manufactured in India and is available for domestic supply as well as export to international markets.Q: What is the process for measuring tap density using this tester?

A: The process involves placing your powder sample in the tester, setting tap parameters, executing tapping cycles to compact the material, and then measuring the samples final volume and mass to calculate tap density.Q: What benefits does the Tap Density Tester - 1951 offer to laboratories and manufacturers?

A: The tester offers accurate and consistent tap density measurements, helps regulate material properties, contributes to meeting industry standards, and supports efficient quality control in manufacturing and research environments.

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 15 Pieces Piece Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

- Main Export Market(s)

- Western Europe, Asia, Australia, Middle East, Central America, Africa, South America, Eastern Europe, North America

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tap/Bulk Density Apparatus Category

Bulk Density Apparatus - 951

Price Range 170000.00 - 400000.00 INR

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 240 x 300 x 350 Millimeter (mm)

Power : 10 Watt (w)

Voltage : 220 Volt (v)

Material : Plastic

|

ESICO INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese